UP3-Aggregate - the strapping press which goes up to

30000 N

For applications that don’t require a high-end solution yet, PAMMINGER offers the UP3 Aggregate.

With a variably adjustable pressing power of up to 30kN, this system also offers a peak output of 140 pallets per hour.

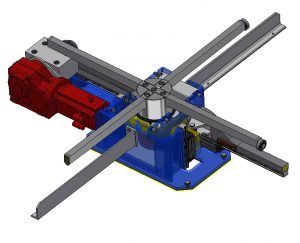

2 column design with rack drive

and a servo motor on board.

Press capacity via servo drive adjustable.

- stable compact design

- strap closure via vibration welding

- Press capacity via servo drive adjustable

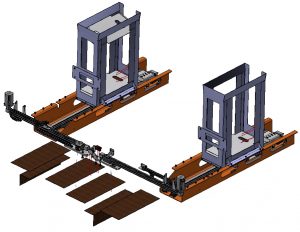

Machine with a maximum possible passage width of 2600 mm

Operation of up to 3 Aggregates

up to 3 strap frames possible

Machine with a maximum clearance of 3000 mm possible, minimal conveying height of 300 mm

sturdy 2 column design with one bolted rack on each side of the 2 columns for the lifting movement.

The weight-optimized Pressing Plate is driven by a servo motor and racks. The machine is designed for a maximum press capacity of 30 kN.

Exact and reproducible press capacity, respectively strapping height via Servo power unit. Strapping aggregates with 90° service position.

Strapping positions/bounding distance: 440 / 625 mm. A strapping aggregate can be moved via linear motor and additional linear guide.

The control of the straping machine consists of a S7-1512 SP. The data transmission of the individual sensors takes place via Profinet. Servo converter and frequency converter are used for motor control respectively for press capacity. User guidance is provided on a 7“ Colour-Touchpanel with different user levels for the supervisor, machine operator and service staff. Altogether 250 strapping programms can be saved.

Lifting and turning device

The lifting and turning device is integrated in the machine frame with an arm intersection of 1300 mm, designed for pallet weight up to 15 kN. The 70 mm lifting and the 90° rotation are utilized by a stationary spur gear motor guiding system. All end positions are electronically monitored, mechanically adjustable and limited. Due to the stationary drive no moveable cables are necessary, i.e. no risk of cable break.

Sequential lance

A lance is required to close the strap frame when strapping a pallet. During pallet transport it drives to the rear end position and therefore requires plenty of space next to the strapping machine.

Due to the design of the sequential lance, it is lifted upwards instead of extended backwards.

This saves up to 50% space in your factory planning.

Edge protection applicator

motor-driven edge protection applicator is integrated at the top of the pressing plate.

For inserting a cardboard blank with a length of 700 mm.

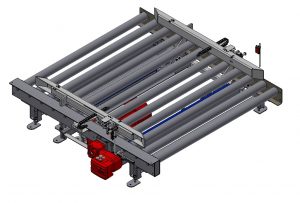

Roller conveyor with centering unit

a motor-driven centring unit can be installed either in the integrated or stand-alone roller conveyor.