Products:

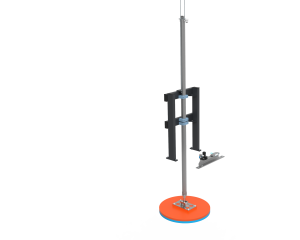

Flyer VA - the all-rounder among stretch wrapping machines

Our rotary arm stretching machine for the commission pallets with unstable stacking of the pallet load.

For line outputs up to 60 pallets per hour.

- film saving

- suitable for pallet sizes up to 4000 x 2000 mm

- ideal for rest and partial pallets

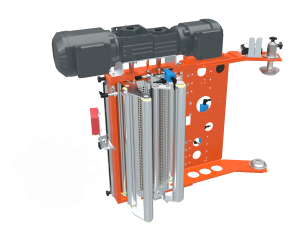

The film carriage

The heart of the machine.

Using the Vario-Power stretching system, the film consumption can be ideally adjusted to the film used and the product which has to be packed.

This ensures the best possible load safety with the lowest possible film consumption.

Simple insertion of the film via an openable film sliding door.

Cover sheet dispenser:

The cover sheet dispenser enables rainproof and dustproof topping of the pallet. Between the wrapping and the unwrapping a cover sheet film has to be laid on the pallet head. Possible water now runs down between the first and the second film layer without touching the product. Due to the freestanding design, a cover sheet can also be placed on very low pallets.

lifting station

To achieve an optimum load safety, the pallet is lifted up by the conveyor technology with all the pallet wood stretched in between.

Film string unit

Automated warehouses do not permit that the pallet wood gets fully wrapped. However, in order to achieve the optimum load safety, the film is shaped up from the bottom to 130mm to a string with a servo drive in the film carriage.

Hold-down clamp

For fixing unstable load units during the stretch process.

Motor driven scissor lifting unit.

Passage cover sheet dispenser

for the dust-tight packaging of your pallets without any reduction in performance.

A cover film is placed on the pallet head during conveying.